KUKA drives project execution

of KUKA cell4_production portfolio with ProMTO®

Klaus Koenig

CEO of KUKA Robotics

Edmund Bahr

Head of Operations Augsburg Plant

Timo Henrich

Project Management office

KUKA Robotics delivers robots, production cells and software for welding, handling, machining and processing to tier 1 suppliers and general industry customers globally.

Customers have very high performance, delivery and budget demands. Despite executing more than 300 projects a year, KUKA needs to be flexible enough to provide each customer a cost-efficient solution for their project. To fulfill this need a portfolio of highly performing, attractively priced and digitally connected production cells serves as the core element of solution projects.

These cells are called KUKA cell4_production and were developped from concept to realization within the course of the project work with IMPREOS. They are KUKA‘s answer to their customers‘ production needs around the globe.

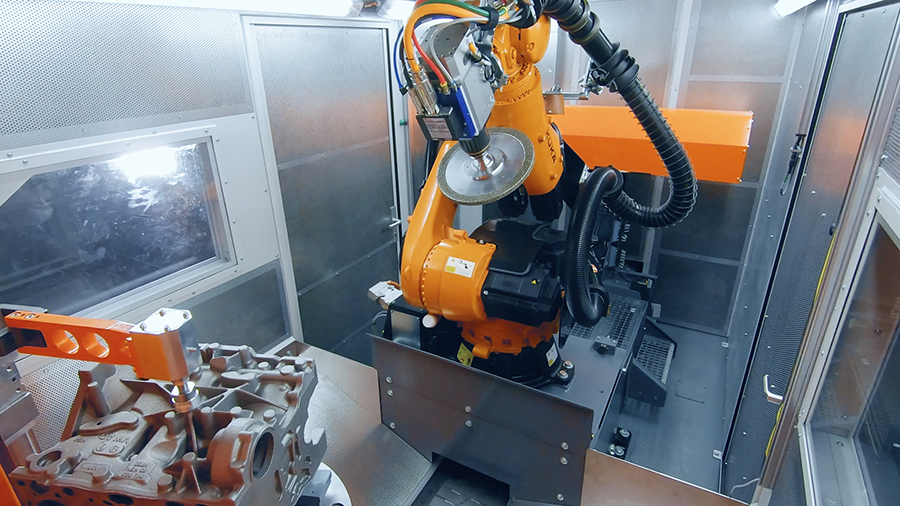

Cell4_Pre-Machining (digital prototype)

Cell4_Pre-Machining (Realization)

“We must ensure that each project is on-time, on-budget and on-spec.“, says Edmund Bahr. “So having the smart cells is not enough. For KUKA it is just as important to have a lean and efficient multi-project management for all open projects running in parallel.“

“Our existing processes led to a lot of functional interfaces and frequent work interruptions. Therefore the project managers were overloaded with creating visibility and juggling priorities instead of solving problems. The result was delays in delivery and budget overruns.“

“We realized that we needed better transparency to make more efficient use of our team‘s resources, especially the project managers. So we were looking for a new, faster and smarter way of working, suitable to drive KUKA cell4_production.“

Edmund Bahr

Head of Operations Augsburg Plant

KUKA Robotics introduced ProMTO® as analytics optimizer. It simplified and accelerated the entire execution process, which is now based on standardized sprint phases.

“It helped to identify issues much earlier and solve them together as team. The PMOs and project managers were able to concentrate on their actual job: manage projects.“, says Timo Henrich, a manager in the Project Management Office (PMO).

In the first six weeks it was all about improving on-time delivery. “We brought all of our team members together and got them to practise the standard optimization procedures again and again.“ After that the focus was on meeting clients‘ project budgets. “Identifying how to manage our bill-of-materials more efficiently was key, for example. Finally we worked intensively on accelerating our onsite commissioning.“

“To drill deeper I use dashboards a lot.“, says Timo. “I think the secret formula is the combination of three things: full process transparency, the positive empowerment of the work team with data-driven insights, and very smart optimization levers.“

Timo Henrich

Project Management office

“Within one week we gained a level of transparency over our 300 projects that we had never had before.“, says CEO Klaus Koenig. And the team was in full control. After just three months KUKA had achieved zero days of delay across all project deliveries. After six months budget overruns had been reduced by 14 percentage points to zero overrun.

“We are now the benchmark for multi-project management in the group and ready to realize further growth with our KUKA cells4_production“, says Klaus.

Klaus Koenig

CEO of KUKA Robotics